| Oh and collegaues report a straightforward synthesis route for manufacturing colored electrophoretic inks for emerging flexible displays and E-paper applications. |

Reviewed by Jeff Morse, PhD., National Nanomanufacturing Network

Electrophoretic image display (EPID) technologies are generating significant promise for E-books, E-newspapers, and low-power portable display applications having high brightness, good contrast ratio, and reduced manufacturing costs. EPIDs use fluorescent nanoparticles to display images and text by means of charged particle motion in response to an applied voltage. To date, inorganic materials such as TiO2, ZnO2, ZrO, and Al2O3 have been investigated for their enhanced optical and electronic properties resulting from the quantum confinement effects. Despite the enhanced properties of these inorganic materials, other issues including response speed, brightness, and material brittleness must be improved in order to compete for these new market applications.

In contrast, organic nanoparticles for electrophoretic inks have the advantages of being lighter weight and having higher mobility than inorganic particles, thereby improving the responsivity to electric field stimulus. While organic nanoparticles for colored inks would enable a lower-cost pathway to manufacturing, the issue remains to control the size and size distribution of the structures generated via batch processes.

Recently, Oh and colleagues reported on the use of dispersion polymerization of polystyrene (PS) and 4-vinylpyridine (4VP) in methanol-water suspensions using poly(N-vinylpyrrolidone) (PVP) to stabilize the manufacturing process. In addition to controlling the particle size, the chargeability of the particles—a key factor for the speed and efficiency of the EPID—must be controlled through the use of charge control additives. In this work, the authors investigated the polystyrene encapsulation method, further exploiting the highly alkaline nature of 4VP to enhance the encapsulation process.

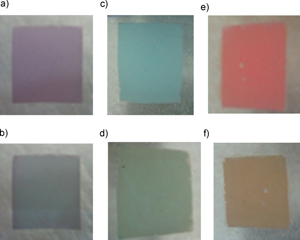

In characterizing the synthesized organic nanoparticles, the authors found that the size and distribution of the polymer particles could be controlled by the amount of ionic surfactant added to the solution. Both SDS and CTAB were added in volume fractions from 1-5%, with the effect that particle size decreased with increased surfactant. This resulted from the increased number of nucleation sites provided by the added surfactant, as well as the added stability for the grown particles, thereby producing particles of uniform shape and size. The authors further prepared an EPID cell using the colored ink nanoparticles. From this testing the electrophoretic mobility of the specific nanoparticles was determined. Similarly, the mobility exhibited a dependence on the amount of ionic surfactant used in the synthesis process.

Therefore, a straightforward synthesis route has been reported for manufacturing colored electrophoretic inks for emerging flexible displays and E-paper applications. Both the size and surface charge density of the particles could be controlled through the synthesis, with the mobility of the ink particles being dictated by the charge of the embedded ionic surfactants.

Image reproduced from Oh SW, et. al. 2009. Encapsulated-Dye All-Organic Charged Colored Ink Nanoparticles for Electrophoretic Image Display. Advanced Materials. 21:1-5. DOI: 10.1002/adma.200901595. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported.