| Zhang et.al., reported on an approach to synthesize thick mesoporous inorganic oxide films in order to harvest more incident solar radiation, thereby enhancing the efficiency of the solar cell. |

Reviewed by Jeff Morse, PhD., National Nanomanufacturing Network

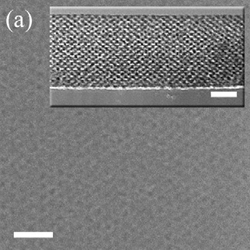

Mesoporous metal oxide thin films have been created by exploiting block-copolymer self assembly approaches to create well-ordered templates. The metal oxide mesopore structure is formed by additive solution chemistry wherein the polymer hydrophilic-hydrophobic blocks self-assemble into a liquid crystal mesophase surrounded by the inorganic oxide network. The mesoporous inorganic oxide structure is formed after subsequent evaporation of solvents, and removal of the organic template by a calcination step. Using this evaporative induced self-assembly (EISA) method, it is possible to fabricate individual mesoporous metal oxide films with thicknesses on the order of 300nm and pore domain size on the order of 10-15 nm. These resulting structures have device implications for highly ordered, thin film nanocomposites by design, although many applications require further versatility in the resulting structure of the mesoporous inorganic oxide.

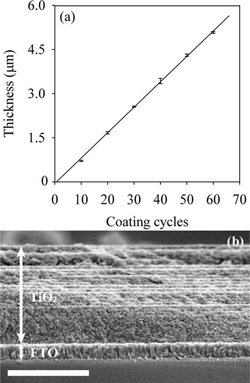

Recently, Zhang et.al., reported on an approach to synthesize much thicker mesoporous titania films in order to harvest more of the incident solar radiation, thereby enhancing the efficiency of the solar cell. In their study, the authors investigated the combination of EISA with layer-by-layer deposition in order to build the mesoporous titania structure up to thicknesses on the order of several microns, better matching the photon absorption length. The challenge in this approach is to maintain the accessibility of the dye to the titania pore structure to maintain a continuous interface between the absorbing dye material and the electron conducting titania. Additional challenges include maintaining the pore domain characteristics and minimizing the stress formed in the film with increasing thickness in order to prevent cracking or delamination from occurring.

The authors describe an innovative method to form thick mesoporous inorganic oxide films. The approach yields uniform and repeatable pore structures via a layer-by-layer deposition process. Further reduction in film stress with increased thickness could potentially mitigate cracking and delamination effects, thereby providing a unique approach to create mesoporous superstructures for a wider range of applications.

Images reproduced with permission from Zhang Y, et. al. 2009. Highly Efficient Dye-Sensitized Solar Cells of Thick Mesoporous Titania Films Derived from Supramolecular Templating. Nanotechnology 20 (505602). DOI: 10.1088/0957-4484/20/50/505602.