While significant challenges exist to transition production lines to address emerging markets, investment in these strategies will provide benefits in terms of economic growth, jobs, and other U.S. interests including security. Recently, the National Academies held a one day conference on Flexible Electronics for Security, Manufacturing, and Growth in the U.S. underscoring the impact of flexible electronics and manufacturing on national and global competitiveness.

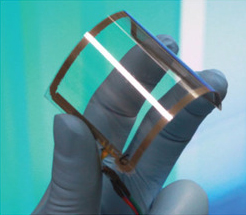

From a technology standpoint, roll-to-roll processes and similar print and coating methods are presently being explored for applications including batteries and energy storage, solar photovoltaics, flexible displays, lighting, and electronics. In most cases, design and fabrication modifications are necessary in order to make the process compatible with the flexible substrate material, which usually includes thermal, mechanical, and chemical considerations. In terms of implementation of specific nanomaterials, transparent electrodes for displays and solar photovoltaics are a prime example. Several nanomaterials have been developed and made commercially available, including silver nanoparticle and carbon nanotube inks, which have additionally been demonstrated as coatings via roll-to-roll processes. Recently, Bae et.al. have demonstrated the growth of large area graphene films surpassing the industry standards for transparent electrodes and subsequent dry transfer process via roll-to-roll production techniques [1]. As another example, solution-based approaches that have previously been demonstrated for fabricating nanostructured carbon for battery and supercapacitor electrodes are now being scaled to flexible substrate and roll-to-roll process platforms.

Additional nanomanufacturing processes that have been adapted to flexible web processes include imprint lithography to fabricate thin film transistor arrays and circuits, along with directed and additive driven assembly methods to form ordered metamaterials and aligned nanostructures. While these emerging processes are at the early stages of scientific research and remain in the laboratory, integration strategies are evolving for numerous application areas including autonomous sensors, energy and power, communications, and smart textiles. Combining these innovative processes and unique materials within a common process platform through an existing industry provides a transformative impact towards U.S. competitiveness, and potentially enables a long term sustainable industry base for critical consumer products. As the opportunities emerge, several issues and challenges become clear, including the need for multidisciplinary teaming and collaboration, advanced metrology and process control, process integration, and advanced test-bed platforms to develop these strategies for future manufacturing sustainability.

References

This work is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported.