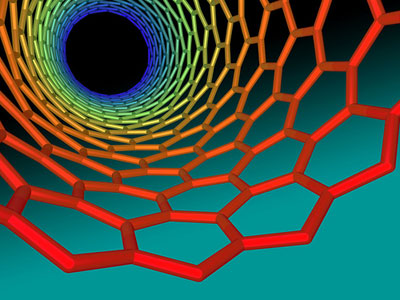

As a definition, nanomanufacturing is the controllable manipulation of materials structures, components, devices, and systems at the nanoscale (1 to 100 nanometers) in one, two, and three dimensions for large-scale reproducibility of value-added components and devices. Nanomanufacturing remains the essential bridge between the discoveries of the nanosciences and real-world nanotechnology products. Nanomanufacturing encompasses bottom-up directed assembly, top-down high resolution processing, molecular systems engineering, and hierarchical integration with larger scale systems. As dimensional scales of materials and molecular systems approach the nanoscale, the conventional rules governing the behavior and properties of these components, devices, and systems change significantly. As such, the behavior of the final product is enabled by the collective performance of the nanoscale building blocks, thereby enabling enhanced performance and functionality.

With this increased emphasis on commercialization, the PCAST report has recommended the development of appropriate methods and models to assess the economic impact of nanotechnology. With this focus, the International Symposium on Assessing the Economic Impact of Nanotechnology was held this past week in Washington, D.C.. The symposium aimed to systematically explore the need for and development of a methodology to assess the economic impact of nanotechnology across whole economies, factoring in many sectors and types of impact, including new and replacement products and materials, markets for raw materials, intermediate and final goods, and employment and other economic impacts. Attendees and participants represented a broad spectrum of backgrounds and expertise, including technology leaders, key decision makers, economists, investors, policy analysts, scientists and engineers from industry, business, government, academia, and the general public. Issues addressed included the scope of economic impacts of nanotechnology, input and output factors, metrics for other technological assessments, and consideration of the appropriateness of these metrics for nanotechnology materials and products. Additional topics discussed included the role of research funding portfolios, intellectual property frameworks, venture capital, public-private partnerships, state and local initiatives, international cooperation, and metrics such as private sector and industry investments, patents and publications, and the development of a technologically-educated workforce as metrics for nanotechnology (NNI).

While the issues associated with such assessments are extremely complex for nanotechnology as a whole, those associated with nanomanufacturing may be a bit more straightforward. In general, nanomanufacturing represents the processes and techniques utilized to produce nano-enabled products. These products include raw or value-added nanomaterials, nano-intermediates, and final integrated products. Yet assessment of economic impact is not always obvious and the assessments become more complicated the further up the value-chain they are positioned. An excellent example is touch screens, which have recently become one of the first examples of a nanomanufacturing technology adopted by the high growth flexible electronics and display industry. The nanotechnology used for touch screens is transparent electrodes as exemplified by silver nanowire or carbon nanotube networks. The value-added components include the raw nanomaterials, the functionalized ink dispersions, the resulting thin film, and the printing or roll-to-roll nanomanufacturing methods. As these components are integrated within the touch screen product, the final product now becomes nano-enabled. However, the discussion as to the fraction of the nano-enabled device included in the context of economic value is very complex.

This discussion is certain to continue, with models being developed, implemented, and fine-tuned as part of the path forward for the NNI and nanomanufacturing, and many future events on nanotechnology will include these topics. For example, the NanoTech Commercialization Conference in Research Triangle, NC April 4-5, 2012 will explore the commercialization of nanotechnologies, while the 2012 Regional, State, & Local Initiatives in Nanotechnology (RSL 2012) Workshop (sponsored by the NNI) will look at the current landscape of U.S. RSL nanotechnology initiatives and their respective health and economic benefits. From this, RSL best practices, business models, and opportunities for partnering, along with the role of RSL nanotechnology in future U.S. economic growth and job creation will be discussed. These discussions are intended to create optimal models for effective public-private partnerships that can facilitate sustainable economic impact, assisting the U.S. in addressing the valley of death by ensuring U.S. leadership in advanced manufacturing. Likewise, the PCAST made a number of recommendations to address this, including the launch of an Advanced Manufacturing Initiative in its June 2011 report. It seems clear that the U.S. perceives that manufacturing is key to future development and effective competitiveness, and possibly that nanomanufacturing within targeted regional hubs or consortia may provide such an advanced manufacturing paradigm.