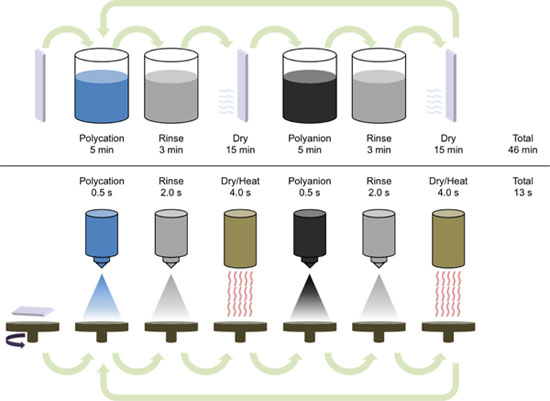

Functional nanocomposite thin films are traditionally synthesized by techniques such as casting or dip-coating wherein the quality and properties of the film are determined by the concentrations of the initial dispersion and casting time, with limited parameters to control or tune the properties of the film. Layer-by-layer (LbL) assembly has emerged as a method to circumvent this issue by offering exquisite control over the composition and properties of a multilayer, polymer-nanostructure materials hybrid, and has become an effective method for synthesis of carbon nanotube (CNT)-polymer composite films. LbL assembly utilizes the sequential deposition of polyelectrolyte pairs through a dip-coating procedure. The deposition of materials during each cycle is self-limiting, dictated by the charge concentration of the polyelectrolyte solution and the surface being coated. Yet LbL assembly is still a relatively slow process, requiring time-scales on the order of days to produce films with targeted conductivity and thickness. Utilizing spraying techniques to apply the polyelectrolyte solutions to the substrate, significant reduction in process time has been demonstrated. While spraying the polyelectrolyte-CNT solution is both materially and temporally efficient, the time requirements to deposit thin films remain excessive for batch and production scale process compatibility.

Recently, Gittleson et. al., reported on the results of the spin-spray layer-by-layer (SSLbL) technique. In order to circumvent the slow drying time associated with gravity based removal of excess solution during each deposition cycle, the authors investigated the benefit of substrate rotation and incorporation of active drying through heating to enable a more facile and comprehensive method to tune the properties of the deposited film. SSLbL-assembled multilayer films provide nanoscale control of film properties by adjustment of process variables including solution concentration, spray time, substrate spin rate, drying time, drying air flow, and time. The precise control offered through this technique, along with the reduction in assembly speed, enables both a method for rapid parametric screening of multicomponent polymer films, as well as an effective path to scaled coating production. The authors selected several CNT-containing polyelectrolyte dispersion solutions in order to confirm the LbL formation mechanism for each polymer system with and without counter-polymer polyelectrolytes.

Owing to the more efficient removal of excess solution using the spin-spray process, a single bilayer SSLbL step deposited a 0.8 nm film in comparison to 3.1 nm per bilayer step for the dip-LbL process. In assessing the process performance, the SSLbL assembly approach demonstrated a 50% reduction in process time per bilayer deposition cycle utilizing the active drying processes. Additionally, the authors noted enhanced electrical properties for films synthesized by SSLbL in comparison to dip-coated LbL processing. Comparison of similar coatings utilizing each technique demonstrated reduced sheet resistance for the SSLbL films resulting from the onset of percolation thresholds in the thinner films. The authors further investigated the practical aspects of the SSLbL films. As an example demonstration, polyelectrolyte-CNT films were characterized for Li-ion battery anode performance, exhibiting competitive performance properties for simple film architectures. Thus a versatile coating approach has been further improved demonstrating scalability for a range of applications. While the SSLbL approach has been demonstrated for wafer or coupon base batch processing, an extension of this technique towards large area printing or web-based process platforms may facilitate implementation towards large-area, high commercial manufacturing platforms.

Reviewed by Jeff Morse, PhD, National Nanomanufacturing Network

- Gittleson FS, Kohn DJ, Xiaokai L, Taylor AD. 2012. Improving the assembly speed, quality, and tunability of thin conductive multilayers. ACS Nano. http://dx.doi.org/10.1021/nn204384f

Figure reprinted with permission from Gittleson FS, Kohn DJ, Xiaokai L, Taylor AD. 2012. Improving the assembly speed, quality, and tunability of thin conductive multilayers. ACS Nano. http://dx.doi.org/10.1021/nn204384f American Chemical Society.