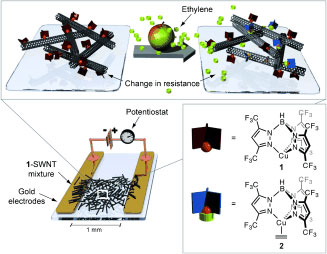

| In order to optimize produce shelf-life from time of harvest through storage and transportation, smart packaging and sensor technologies are readily being explored and evaluated for various scenarios encountered in the horticultural industry. Recently, Esser et. al. reported on the selective detection of ethylene gas using carbon nanotube-based sensors as a means of determining fruit ripeness. |

Reviewed by Jeff Morse, Ph.D., National Nanomanufacturing Network

- Esser B, Schnorr JM, Swager TM. 2012. Selective detections of ethylene gas using carbon nanotube-based devices: Utility in determination of fruit ripeness. Angewandte Chemie International Edition 51(23). http://dx.doi.org/10.1002/anie.201201042

Horticultural industries face significant challenges in determining the optimal time for harvesting, storage, and transport of produce in order to avoid substantial degradation and waste due to overripening. The culprit for this is ethylene, the smallest of plant hormones, which plays a key role in many plant developmental processes, including the ripening of fruits and vegetables. The ripening process is the result of ethylene binding to the receptor ETR1, leading to the translation of ripening genes, and subsequently the production of enzymes that induce the visible signs of ripening. Measures of the internal ethylene concentration in fruit, for example, can provide an indicator to determine the time to harvest, and monitoring of ethylene levels during storage and transportation can avoid overripening of the fruit. Additionally, methods to scavenge ethylene could extend the shelf-life of produce.

Sensor characterization was conducted using a controlled gas flow consisting of nitrogen carrier gas with various concentrations of ethylene gas introduced to the stream through an ethylene permeation tube. The stream then flowed through a control valve to the sensing chamber with the device. The resistance change exhibited a linear response to ethylene concentration over a range of 0.5-50 ppm. Furthermore, the SWNT-copper complex exhibited consistent, stable response even during exposures that included the presence of carbon dioxide (CO2) and acetylene (C2H2). Experiments were further devised in which the sensors were used to monitor actual samples of fruit over a period of several weeks. The results were compared to the expected ripening processes for the different fruits utilized in the experiment, exhibiting excellent correlation to visual observations as well. Thus, a nanotechnology sensor has been demonstrated with the capability to monitor the production of ethylene by produce, thereby providing a means to optimize the storage and transportation of the produce for optimal shelf-life. Such a technology may be incorporated as a smart packaging concept, which may further incorporate similar materials that can block or bind the ethylene to extend the shelf-life of the produce.

Figure posted from Esser B, Schnorr JM, Swager TM. 2012. Selectivedetections of ethylene gas using carbon nanotube-based devices: Utility in determination of fruit ripeness. Angewandte Chemie International Edition 51(23). http://dx.doi.org/10.1002/anie.201201042 . Copyright Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. Permission pending.