|

The NNN Newsletter

The Nanomanufacturing Revolution and Continuing Impact: Nanomanufacturing Summit 2011

As the impact of public and private sector investments in nanotechnology for more than a decade now continues to evolve, we are moving into a new era whereby a decade of intense scientific research gives way to fundamentally new products that will have significant societal and economic impact. As the predicted billions and trillions of dollars of emerging nano-enabled products enter the marketplace, the interest and focus on nanomanufacturing and the commercialization of nanotechology will grow. Nanomanufacturing processes previously considered fundamental science are now key enablers to solve critical issues in the evolution of many products, fueling the innovation cycle to realize completely new products. These processes include bottom-up directed assembly, top-down high-resolution patterning and manipulation, molecular and biological systems engineering, and hierarchical integration across multiple length scales. As the impact of public and private sector investments in nanotechnology for more than a decade now continues to evolve, we are moving into a new era whereby a decade of intense scientific research gives way to fundamentally new products that will have significant societal and economic impact. As the predicted billions and trillions of dollars of emerging nano-enabled products enter the marketplace, the interest and focus on nanomanufacturing and the commercialization of nanotechology will grow. Nanomanufacturing processes previously considered fundamental science are now key enablers to solve critical issues in the evolution of many products, fueling the innovation cycle to realize completely new products. These processes include bottom-up directed assembly, top-down high-resolution patterning and manipulation, molecular and biological systems engineering, and hierarchical integration across multiple length scales.

The impact of nanomanufacturing has already begun to be realized with examples that include directed self-assembly (DSA) for high-density bit patterned data storage media, the inclusion of DSA in the roadmap for the semiconductor industry, and the scaled production of nanocomposites and nanomaterials via both new and existing manufacturing infrastructure. Nanostructured materials such as carbon nanotubes, graphene, and a range of nanoparticle materials have achieved new levels of performance for applications such as transparent electrodes, thin film transistors, next generation electronics, energy storage, nanomedicine, renewable energy, and resource remediation. This range of nano-enabled products represents both significant markets as well as critical national needs.

More...

Regards,

Jeff Morse, Managing Director,

National Nanomanufacturing Network

Learn More about the

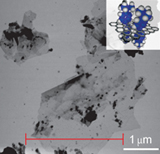

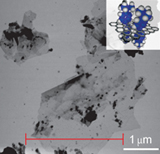

Graphene Mass Production Comes Closer with Bulk Wet Chemical Exfoliation of Graphite

There are already several technologies that potentially allow mass production of graphene sheets--by chemical vapor deposition growth; by epitaxial growth of graphene on top of a metal surface; and various wet chemical processes of processing graphene in solution by exfoliating graphite. In new work, Englert and a group of scientists from the University Erlangen-Nuremberg, led by Andreas Hirsch, have now demonstrated the first bulk wet chemical exfoliation of graphite in association with an in situ covalent functionalization of intermediately generated graphene. With this novel chemical method, it is now possible to achieve covalently bonded functionalities without mechanical or sonochemical treatment. The covalent functionalization also protects the single-layer graphene from reaggregation and substrate-induced doping. More.... There are already several technologies that potentially allow mass production of graphene sheets--by chemical vapor deposition growth; by epitaxial growth of graphene on top of a metal surface; and various wet chemical processes of processing graphene in solution by exfoliating graphite. In new work, Englert and a group of scientists from the University Erlangen-Nuremberg, led by Andreas Hirsch, have now demonstrated the first bulk wet chemical exfoliation of graphite in association with an in situ covalent functionalization of intermediately generated graphene. With this novel chemical method, it is now possible to achieve covalently bonded functionalities without mechanical or sonochemical treatment. The covalent functionalization also protects the single-layer graphene from reaggregation and substrate-induced doping. More....

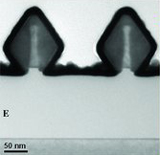

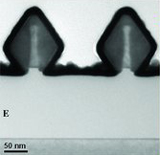

Fabrication of Nanoscale Plasmonic Sensing Structures Over Large Areas

Plasmonic sensors provide a means of detecting chemical and biological species through the observation of spectral features by measurement techniques such as surface enhanced Raman spectroscopy (SERS) or surface plasmon resonance (SPR). Plasmonically active SERS substrates, such as metallic gratings or periodic metal nanowire arrays, have sub-wavelength features that enable direct coupling of normally incident electromagnetic (EM) radiation to surface plasmons. The high detection sensitivity of these methods is facilitated by EM field enhancements in the vicinity of the metallic nanostructures. Field enhancements can be achieved by controlling the spacing between nanostructures as well as the features along the length of individual nanostructures. In order to develop a full-scale plasmonic sensor, periodic nanostructures must be replicated over large-area surfaces, such as six-inch silicon wafers. By incorporating hybrid top-down and bottom-up synthesis, a versatile approach has been demonstrated for fabricating large-area plasmonic sensors. The ability to fine tune nanostructure features over large areas renders this technique highly adaptable, thereby opening up new opportunities for plasmonic sensor applications. More.... Plasmonic sensors provide a means of detecting chemical and biological species through the observation of spectral features by measurement techniques such as surface enhanced Raman spectroscopy (SERS) or surface plasmon resonance (SPR). Plasmonically active SERS substrates, such as metallic gratings or periodic metal nanowire arrays, have sub-wavelength features that enable direct coupling of normally incident electromagnetic (EM) radiation to surface plasmons. The high detection sensitivity of these methods is facilitated by EM field enhancements in the vicinity of the metallic nanostructures. Field enhancements can be achieved by controlling the spacing between nanostructures as well as the features along the length of individual nanostructures. In order to develop a full-scale plasmonic sensor, periodic nanostructures must be replicated over large-area surfaces, such as six-inch silicon wafers. By incorporating hybrid top-down and bottom-up synthesis, a versatile approach has been demonstrated for fabricating large-area plasmonic sensors. The ability to fine tune nanostructure features over large areas renders this technique highly adaptable, thereby opening up new opportunities for plasmonic sensor applications. More....

NanoBusiness NYC Conference, April 6-7 Agenda

The NanoBusiness Commercialization Association has announced their updated program for the 2nd Annual NanoBusiness NYC Conference, which will be held will be held April 6 & 7 at the Marriott Marquis Times Square in New York City. The theme of the 2011 Conference is The Next Decade of Nanotechnology. The NYC Event brings together New York's investment community to analyze the commercialization of nanotechnology products. The event includes both keynote presentations and panel discussions. More.... The NanoBusiness Commercialization Association has announced their updated program for the 2nd Annual NanoBusiness NYC Conference, which will be held will be held April 6 & 7 at the Marriott Marquis Times Square in New York City. The theme of the 2011 Conference is The Next Decade of Nanotechnology. The NYC Event brings together New York's investment community to analyze the commercialization of nanotechnology products. The event includes both keynote presentations and panel discussions. More....

Read more on  |

Advertisement

Upcoming Events

April 5 - 6, 2011

Nanomanufacturing Micromanufacturing Conference & Exhibits

April 6 - 7, 2011

2011 NanoBusiness NYC Conference

April 9 - 11, 2011

ICMSE 2011

April 14, 2011

Nanomaterials for Biological Applications

April 24 - 29, 2011

Graphene Week

April 25 - 29, 2011

MRS Spring Meeting 2011

View Full Calendar

Upcoming Calls

NANOARCH'11

Submission Deadline April 10

Greener Nano 2011

Poster Abstracts still being accepted

AVS 58th International Symposium and Exhibition

Submission Deadline May 4

View All Calls

Advertisement

Recently Published

From Our Affiliates

Photoinduced Ordering of Block Copolymers

Nano Letters 11(3):1153-1160

Gelation behavior of polysaccharide-based interpenetrating polymer network (IPN) hydrogels

Rheologica Acta50(1):39-52

Effect of Processing Parameters on the Electrophoretic Deposition of Carbon Black Nanoparticles in Moderately Viscous Systems

Langmuir 27(6):3166-3173

Design, Fabrication, and Characterization of Three-Dimensional Single-Walled Carbon Nanotube Assembly and Applications As Thermal Sensors

IEEE Transactions on Nanotechnology 10(1):13-20

Biofunctionalized nanoneedles for the direct and site-selective delivery of probes into living cells

Biochimica Et Biophysica Acta-General Subjects 1810(3) Sp. Iss.:330-338

Advertisement

Affiliated Centers

|

Volume

4 Issue 3 - March 2011

Volume

4 Issue 3 - March 2011 As the impact of public and private sector investments in nanotechnology for more than a decade now continues to evolve, we are moving into a new era whereby a decade of intense scientific research gives way to fundamentally new products that will have significant societal and economic impact. As the predicted billions and trillions of dollars of emerging nano-enabled products enter the marketplace, the interest and focus on nanomanufacturing and the commercialization of nanotechology will grow. Nanomanufacturing processes previously considered fundamental science are now key enablers to solve critical issues in the evolution of many products, fueling the innovation cycle to realize completely new products. These processes include bottom-up directed assembly, top-down high-resolution patterning and manipulation, molecular and biological systems engineering, and hierarchical integration across multiple length scales.

As the impact of public and private sector investments in nanotechnology for more than a decade now continues to evolve, we are moving into a new era whereby a decade of intense scientific research gives way to fundamentally new products that will have significant societal and economic impact. As the predicted billions and trillions of dollars of emerging nano-enabled products enter the marketplace, the interest and focus on nanomanufacturing and the commercialization of nanotechology will grow. Nanomanufacturing processes previously considered fundamental science are now key enablers to solve critical issues in the evolution of many products, fueling the innovation cycle to realize completely new products. These processes include bottom-up directed assembly, top-down high-resolution patterning and manipulation, molecular and biological systems engineering, and hierarchical integration across multiple length scales. There are already several technologies that potentially allow mass production of graphene sheets--by chemical vapor deposition growth; by epitaxial growth of graphene on top of a metal surface; and various wet chemical processes of processing graphene in solution by exfoliating graphite. In new work, Englert and a group of scientists from the University Erlangen-Nuremberg, led by Andreas Hirsch, have now demonstrated the first bulk wet chemical exfoliation of graphite in association with an in situ covalent functionalization of intermediately generated graphene. With this novel chemical method, it is now possible to achieve covalently bonded functionalities without mechanical or sonochemical treatment. The covalent functionalization also protects the single-layer graphene from reaggregation and substrate-induced doping.

There are already several technologies that potentially allow mass production of graphene sheets--by chemical vapor deposition growth; by epitaxial growth of graphene on top of a metal surface; and various wet chemical processes of processing graphene in solution by exfoliating graphite. In new work, Englert and a group of scientists from the University Erlangen-Nuremberg, led by Andreas Hirsch, have now demonstrated the first bulk wet chemical exfoliation of graphite in association with an in situ covalent functionalization of intermediately generated graphene. With this novel chemical method, it is now possible to achieve covalently bonded functionalities without mechanical or sonochemical treatment. The covalent functionalization also protects the single-layer graphene from reaggregation and substrate-induced doping.  Plasmonic sensors provide a means of detecting chemical and biological species through the observation of spectral features by measurement techniques such as surface enhanced Raman spectroscopy (SERS) or surface plasmon resonance (SPR). Plasmonically active SERS substrates, such as metallic gratings or periodic metal nanowire arrays, have sub-wavelength features that enable direct coupling of normally incident electromagnetic (EM) radiation to surface plasmons. The high detection sensitivity of these methods is facilitated by EM field enhancements in the vicinity of the metallic nanostructures. Field enhancements can be achieved by controlling the spacing between nanostructures as well as the features along the length of individual nanostructures. In order to develop a full-scale plasmonic sensor, periodic nanostructures must be replicated over large-area surfaces, such as six-inch silicon wafers. By incorporating hybrid top-down and bottom-up synthesis, a versatile approach has been demonstrated for fabricating large-area plasmonic sensors. The ability to fine tune nanostructure features over large areas renders this technique highly adaptable, thereby opening up new opportunities for plasmonic sensor applications.

Plasmonic sensors provide a means of detecting chemical and biological species through the observation of spectral features by measurement techniques such as surface enhanced Raman spectroscopy (SERS) or surface plasmon resonance (SPR). Plasmonically active SERS substrates, such as metallic gratings or periodic metal nanowire arrays, have sub-wavelength features that enable direct coupling of normally incident electromagnetic (EM) radiation to surface plasmons. The high detection sensitivity of these methods is facilitated by EM field enhancements in the vicinity of the metallic nanostructures. Field enhancements can be achieved by controlling the spacing between nanostructures as well as the features along the length of individual nanostructures. In order to develop a full-scale plasmonic sensor, periodic nanostructures must be replicated over large-area surfaces, such as six-inch silicon wafers. By incorporating hybrid top-down and bottom-up synthesis, a versatile approach has been demonstrated for fabricating large-area plasmonic sensors. The ability to fine tune nanostructure features over large areas renders this technique highly adaptable, thereby opening up new opportunities for plasmonic sensor applications.  The NanoBusiness Commercialization Association has announced their updated program for the 2nd Annual NanoBusiness NYC Conference, which will be held will be held April 6 & 7 at the Marriott Marquis Times Square in New York City. The theme of the 2011 Conference is The Next Decade of Nanotechnology. The NYC Event brings together New York's investment community to analyze the commercialization of nanotechnology products. The event includes both keynote presentations and panel discussions.

The NanoBusiness Commercialization Association has announced their updated program for the 2nd Annual NanoBusiness NYC Conference, which will be held will be held April 6 & 7 at the Marriott Marquis Times Square in New York City. The theme of the 2011 Conference is The Next Decade of Nanotechnology. The NYC Event brings together New York's investment community to analyze the commercialization of nanotechnology products. The event includes both keynote presentations and panel discussions.