Presented here is a method for assembling homogenous films of controllable thickness comprised of hybrid nanostructures on a roll-to-roll platform directly from solution. Using surfactant-free mixtures of nanoparticles, nanotubes, nanosheets, and any combination thereof, film fabrication may be achieved that maintains the chemical and physical properties inherit to the constituent material that is not limited by the presence of surfactants or impurities. Using this technique, researchers may demonstrate the viability of scalable production of a synthesized material.

Landon Oakes, Adam Cohn, Trevor Hanken, Rachel Carter, and Cary L. Pint

Department of Mechanical Engineering, Vanderbilt University

Cut and clean the substrate to the desired size and load onto a roller

Disperse the active materials together in solution for a total concentration of 0.5 mg/ml in an organic solvent (e.g. 1-methyl-2-pyrrolidone (NMP))

Apply sonication to disperse and/or exfoliate the nanostructures in solution.

Centrifuge the solution to purify the nanostructures in solution.

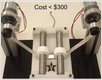

Fill a reservoir between the counter electrode and conductive roller with the nanomaterial suspension.

Apply a bias between the active electrode (i.e. roller) and counter electrode in solution and then roll the substrate through solution. The rate at which the roller is moved through solution in combination with the applied voltage determines film thickness.

After the coating process has fully completed, turn the bias off and let substrate dry.

The precise film composition may be controlled by varying the relative concentrations of dispersed nanomaterials or their zeta potentials in solution.

A variety of solvents may be used to improve the compatibility of the process with a wider selection of nanostructures.

This process has been shown to improve interparticle conductivity and film adhesion compared with conventional coating processes.

This process may be used in conjunction with nanomaterial syntheses process for one-batch processing of nanomaterial films.2 This process may be used to coat 3-D electrodes such as nickel foam materials. 3 This process may also be used to coat insulating substrates. 4

- Electrode material

- Selected nanomaterials

- Organic solvent

- Sonicator

- Power Supply