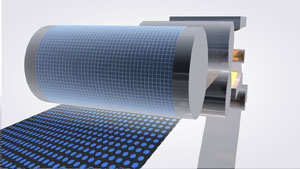

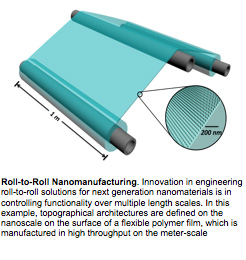

The R2R platform is an industrial vetted way to handle solution-based processes and coatings for high volume manufacturing. R2R processes are implemented for applications as diverse as instant photographic film, separation membranes, filtration media, advance printing and holographic coatings, polymer anti-shatter films for car windshields, flexible solar panels, composite electrodes on metal foils for lithium-ion batteries, and macroscale patterning of metal interconnects for flexible packaging of electronic components. Currently, manufacturers are looking for new innovative continuous-feed processes for printing materials and structures onto roll-based flexible substrates. In particular, there is considerable interest in adapting R2R technologies for the extreme miniaturization of critical feature sizes to the nanoscale. This intersection of nanofabrication with R2R processes has considerable potential to spur innovation and economic growth. Nanofabrication for R2R process platforms represents a disruptive manufacturing technology involving solution-processed, multi-layer precision coatings with functionalized nanostructures, materials, and patterning capability to realize unprecedented properties and functionalities for next generation consumer products. Commercial products and applications impacted by this approach include displays, lighting, energy storage, electronics, and solar photovoltaics. These high-value consumer electronics are predicted to see double-digit market growth beyond the next decade (IDTechEx 2009-2029 Market Report). Incorporation of emerging nanofabrication methods within R2R manufacturing processes will make it possible to economically generate high value-added technology products at meters-per-minute rates on plastic film, paper, or foil, achieving feature dimensions as small as ten nanometers over areas encompassing billions of identical devices. Meeting this challenge is a key to high-rate manufacturing of nano-enabled products and for establishing viable industrial-scale manufacturing platforms for continuous large-area roll-to-roll processing.

The workshop participants successfully identified key barriers to the adoption of nanofabrication processes within R2R manufacturing platforms, as well as to accelerating the commercialization of nano-enabled flexible electronics consumer products. Several approaches were identified that would enhance U.S. competitiveness in this area, including the need for standards to enable product integration across emerging supply lines, improved metrology and in-line characterization, scaled process control and modeling, new materials, and improved off-line characterization tools for product development. Discussants considered the establishment of infrastructure, including possible shared demonstration facilities, where academic research could be transferred and scaled to industrially meaningful process scales, working closely with industry to accelerate the adoption of advanced nanomanufacturing processes. The goal of such a consortium or industry hub would be to enhance broad based industry growth impacting numerous product and application areas, as well as advance the performance of key intermediate technologies (e.g; barrier films, transparent conductors, high-k dielectrics, etc.) that impact different product applications. Subsequent creation of an industry network to further elucidate and resolve such critical issues would be advantageous to U.S. competitiveness in this area.