Nanolithography is one of the enabling technologies of nanomanufacturing. Generally, lithography tools with high throughput (e.g. photolithography) tend to have lower resolution, while lithography tools with high resolution (e.g. electron beam direct write) tend to have lower throughput. Nanoimprint lithography (NIL)1, on the other hand, has both high resolution and high throughput. NIL is based on the mechanical deformation of a resist at the nanometer scale rather than local chemical reaction by radiation. The information content in the mask, or mold as conventionally called in NIL, is presented in the form of topography rather than light transmission function as in photolithography. During a NIL process, patterns in the mold are duplicated into the resist by pressing the mold onto the resist. It is essentially a mechanical process, hence there is no diffraction limit, so NIL has high resolution; it is a parallel process, unlike electron-beam direct write (EBL), which is a serial process, so it has high throughput. NIL was first put onto the ITRS (International Technology Roadmap for Semiconductor) roadmap as an alternative lithography tool in 2003, and it is listed as an alternative for 16 nm and below as of ITRS 2011 update. It is used in research labs and universities to fabricate a wide range of nano-devices, and getting used more and more in industrial applications, such as high density magnetic recording and sub-wavelength optical elements.

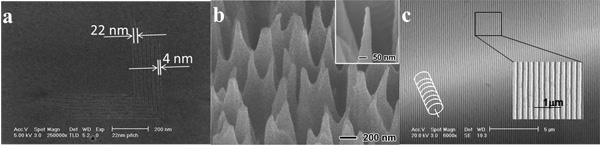

Prof. Wu at University of Southern California together with his former colleagues at Hewlett-Packard and collaborators have made significant progresses on NIL technology and demonstrated numerous applications using NIL. Sub-5 nm resolution of nanoimprint has been demonstrated2. For example, Fig. 1a shows the capability of patterning dense lines at sub-5 nm line-width and 11 nm half-pitch and sharp corners. While most other nanolithography tools are only capable of patterning 2-D patterns, NIL can be used to pattern 3-D structures. As shown in Fig. 1b, nanocones with sharp tips (i.e. radius less than 10 nm) and height up to 2 micron3. NIL was used to fabrication nanostructures not only on conventional substrates but also on non-flat surfaces. Fig. 1c shows gratings at 100 nm half-pitch fabricated on the highly curved surface of a single-mode optical fiber4.

Prof. Wu and co-workers invented the approach of NIL based on wafer bowing5, which simplifies NIL machine design and enables excellent overlay accuracy at reasonable cost. Based on this concept, they developed two NIL machines. One is a compact module which can be incorporated into a mask aligner to transform it into a nanoimprint machine capable of doing both alignment and nanoimprinting. The other is a stand-alone machine. They achieved multi-layer NIL with 60 nm overlay alignment using this machine.6 This technology has been commercialized through IP licensing.

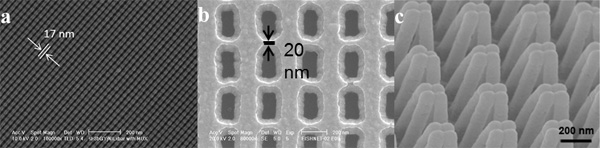

NIL has numerous applications. Prof. Wu and co-workers have fabricated several generations of nano-crossbar memory (i.e. memristor) circuits, with half-pitch down to 17 nm (storage density of 100 Gbits/cm2), as shown in Fig. 2a7. Those memristor crossbar circuits were also vertically integrated with CMOS substrates that were fabricated at a commercial CMOS fabrication facility. This demonstration chip provided an FPGA-like functionality, with memristors as the configuration bits and routing switches for the data path in the FPGA. The memristors are configured through the CMOS configuration circuitry, leading to a new type of hybrid computing architecture that puts the memristors into real applications. The successful integration demonstrates that NIL is compatible with commercial IC fabrication processes8. One example of nano-photonics applications is optical negative refractive index meta-materials (NIMs). NIMs are artificial materials with nanostructure patterns, which have both negative permittivity and permeability in the same frequency range due to resonant properties of the nanostructure, and hence exhibit a negative refractive index in this frequency. By designing the nanostructure, many unique properties, which do not exist in nature, can be realized. By using NIL, several types of negative index meta-materials (NIMs) working at near-IR range (i.e. 1.55 micron wavelength) were fabricated. Those included the first NIM working at near-IR fabricated by NIL9, the first ultra-fast optical modulation using NIMs (Fig. 2b) with a relaxation time of only 0.7 ps10 and the first third harmonic generation using NIMs11. Several highly sensitive surface enhanced Raman spectroscopy (SERS) sensors based on 3-D nanostructures (Fig. 2c) were fabricated by NIL, too12. Those sensors have been used to detect trace amount chemicals, such as pesticides.

References

- Chou SY, Krauss PR and Renstrom PJ. 1995. Imprint of sub‐25 nm vias and trenches in polymers. Applied Physics Letters. 67(21): 3114-3116. http://dx.doi.org/10.1063/1.114851

- Li WD, Wu W, and Williams RS. 2012. Combined helium ion beam and nanoimprint lithography attains 4nm halfpitch dense patterns. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures 30(6). http://dx.doi.org/10.1116/1.4758768

- Wu W, Hu M, Ou FS, Li Z, and Williams RS. 2010. Cones fabricated by 3D nanoimprint lithography for highly sensitive surface enhanced Raman Spectroscopy. Nanotechnology. 21(25). http://dx.doi.org/10.1088/0957-4484/21/25/255502 FIGURE 1b = article figure 2b (no permissions)

- Li Z, Gu Y, Wang L, Ge H, Wu W, Xia Q, Yuan C, Chen Y, Cui B, and Williams RS. 2009. Hybrid nanoimprint−soft lithography with sub-15 nm resolution. Nano Letters. 9(6): 2306-2310. http://dx.doi.org/10.1021/nl9004892 FIGURE 1c = figure 4b article (permission cleared)

- Wu W, Tong WM, Bartman J, Chen Y, Walmsley R, Yu Z, Xia Q, Park I, Picciotto C, Gao J, Wang SY, Morecroft D, Yang J, Berggren KK, and Williams RS. 2008. Sub-10 nm nanoimprint lithography by wafer bowing. Nano Letters. 8(11): 3865-3869. http://dx.doi.org/10.1021/nl802295n

- Wu W, Walmsley RG, Li WD, Li X, and Williams RS. 2012. Nanoimprint lithography with ≤60 nm overlay precision. Applied Physics A: Materials Science & Processing. 106(4): 767-772. http://dx.doi.org/10.1007/s00339-012-6775-z

- Jung GY, Johnston-Halperin E, Wu W, Yu Z, Wang SY, Tong WM, Li Z, Green JE, Sheriff BA, Boukai A, Bunimovich Y, Heath JR, and Williams RS. 2006. Circuit fabrication at 17 nm half-pitch by nanoimprint lithography. Nano Letters. 6(3): 351-354. http://dx.doi.org/10.1021/nl052110f

- Xia Q, Robinett W, Cumbie MW, Banerjee N, Cardinali TJ, Yang JJ, Wu W, Li X, Tong WM, Strukov DB, Snider GS, Medeiros-Ribeiro G, and William RS. 2009. Memristor−CMOS hybrid integrated circuits for reconfigurable logic. Nano Letters. 9(10): 3640-3645. http://dx.doi.org/10.1021/nl901874j

- Wu W, Kim E, Ponizovskaya Y, Liu Y, Yu Z, Fang N, Shen YR, Bratkovsky AM, Tong W, Sun C, Zhang X, Wang SY, and Williams RS. 2007. Optical metamaterials at near and mid-IR range fabricated by nanoimprint lithography. Applied Physics A: Materials Science & Processing. 87(2): 143-150. http://dx.doi.org/10.1007/s00339-006-3834-3

- Cho DJ, Wu W, Ponizovskaya E, Chaturvedi P, Bratkovsky AM, Wang SY, Zhang X, Wang F, and Shen YR. 2009. Ultrafast modulation of optical metamaterials. Optics Express. 17(20): 17652-17657. http://dx.doi.org/10.1364/OE.17.017652

- Kim E, Wang F, Wu W, Yu Z, and Shen YR. 2008. Nonlinear optical spectroscopy of photonic metamaterials. Physical Review B: Condensed Matter and Materials Physics. 78(11): 113102. http://dx.doi.org/10.1103/PhysRevB.78.113102

Figure 1b reprinted with permission from Wu W, Hu M, Ou FS, Li Z, and Williams RS. 2010. Cones fabricated by 3D nanoimprint lithography for highly sensitive surface enhanced Raman Spectroscopy. Nanotechnology. 21(25). http://dx.doi.org/10.1088/0957-4484/21/25/255502 IOP Science.

Figure 1c reprinted with permission from Li Z, Gu Y, Wang L, Ge H, Wu W, Xia Q, Yuan C, Chen Y, Cui B, and Williams RS. 2009. Hybrid nanoimprint−soft lithography with sub-15 nm resolution. Nano Letters. 9(6): 2306-2310. http://dx.doi.org/10.1021/nl9004892 American Chemical Society.

Figure 2c reprinted with permission from Hu M, Ou FS, Wu W, Naumov I, Li X, Bratkovsky AM, Williams RS, and Li Z. 2010. Gold nanofingers for molecule trapping and detection. Journal of the American Chemical Society. 132(37): 12820-12822. http://dx.doi.org/10.1021/ja105248h American Chemical Society.

Figures 1a, 2a, and 2b are unpublished and are reprinted with permission from Wei Wu, Associate Professor, Department of Electrical Engineering – Electrophysics, University of Southern California.