According to Phil Roberts, CEO of CalBattery, "Billions of dollars of energy are being wasted every year because we can't store electricity affordably and practically." Roberts continued, "Incredibly, some energy storage systems providers and independent power producers today are using hundreds of thousands, if not millions, of small cylindrical cell batteries in massive utility-scale storage systems. This approach is simply too costly and not viable. Large storage must be built from large batteries, not small batteries originally designed for powered hand tools. Our VLF battery has a clear performance and cost advantage in providing the massive currents needed with the minimum materials and battery management components, resulting in a more affordable lithium-ion battery for wide-scale use."

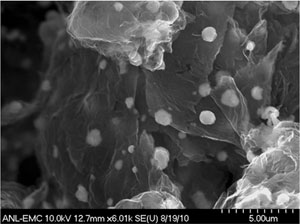

This novel "GEN3" lithium-ion battery will combine Argonne's silicon-graphene battery anode process with other advanced battery materials into the lowest lifecycle cost per watt lithium-ion battery ideally suited for energy storage and EV applications. The key technology advancement is CalBattery will become the first US battery manufacturer to be able to successfully use silicon in its battery anode. Silicon which has the ability to absorb lithium by a factor of 10X has until now not yet proven to be stable enough for battery anode use. While much research today is focused on ways to improve silicon stability, ANL tests indicate this newly patented process that embeds nano-silicon into graphene through a novel chemical vapor deposition (CVD) process will dramatically improve silicon stability by protecting the silicon material as it charges and discharges, extending battery cycle life by 3X.

CalBattery recently entered into an option for an exclusive license from ANL for the CVD process for Large Format battery applications. Plans are to take new ANL and other advanced battery material chemistries and apply them into a superior commercial Very Large Format (VLF) battery for energy storage and electric vehicle applications over the next two years.

Dan Vogler, CTO of Ionex Energy Storage Systems said, "The CalBattery Very Large Format form factor battery is ideally suited for grid-scale 1-25MW energy storage systems and/or in heavy-duty EVs. No other lithium, lead-acid, or flow-battery we have seen today can compete with CalBattery's superior GEN3 lithium-ion battery in terms of easy maintenance, better performance and lower overall use cost."

About California Lithium Battery Inc.

California Lithium Battery Inc. was established in 2011 as a California corporation to develop and manufacture in the US the most technologically advanced and affordable lithium battery for grid-scale energy storage, heavy-duty EV transportation, and consumer electronics. CalBattery was named a finalist in the 2012 DOE's America's Next Top Energy Innovator challenge.

Source: Nanowerk