Incorporation of specific nanostructures and textured patterns on surfaces is a growing area of research for controlling surface wetting properties. By tailoring the hydrophobicity for a given surface, enhanced features may be achieved by design such as anti-icing or anti-fog, self-cleaning and repellency to a range of liquids. Another significant area of application for such surfaces is condensation for industrial processes such as power generation, thermal management, air conditioning, desalination, and transportation. Enhancing the heat transfer during condensation will significantly impact the energy efficiency for these applications, further reducing cost and physical impact on the system. Depending on the wettability of the surface, the condensate either forms as a film or as discrete drops on the surface. The latter is more desirable for effective heat transfer, as a film can behave as a thermal barrier, while the dropwise condensate can be continuously shed allowing for renewed nucleation and growth of drops. As a result of these possible advantages, there has been significant interest in developing superhydrophobic surfaces to promote dropwise condensation. Such surfaces to date have typically incorporated complex surface patterns to obtain extreme non-wetting properties in which droplets are formed and sit atop the surface features. In many cases, the droplets suffer from poor surface mobility and become pinned to the surface features. A possible solution to this issue is intricate surface textures that promote shedding of the coalesced droplets, but these are difficult to create and susceptible to damage.

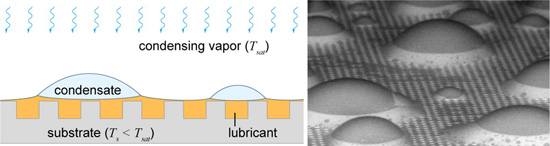

Recently, Anand et al. reported on an alternate approach to promote dropwise condensation in which the condensing surface is microscopically textured and impregnated with a lubricating liquid that will not mix with the condensed liquid. Through selection of the appropriate surface geometry, chemistry, and lubricant, the authors demonstrated a surface having enhanced condensation properties, with water droplets as small 100 µm diameter becoming mobile and continuously swept away, creating new areas for droplet nucleation. The textured surfaces studied by the authors were microfabricated posts of silicon (10µm x 10µm x 10µm) which were then solution coated with a low-energy silane to make them hydrophobic. Two kinds of lubricants were investigated and the impregnation of the surface microstructures was accomplished by dipping the substrate in a bath of the lubricant controlled by a dip-coated system. Utilizing this approach, the surface of the microstructure remains exposed, while the remainder of the surface structure is covered with lubricant.

Reviewed by Jeff Morse, PhD, National Nanomanufacturing Network

- Anand S, Paxson AT, Dhiman R, Smith JD, Varanasi KK. 2012. Enhanced condensation on lubricant-impregnated nanotextured surfaces. ACS Nano. Artilce ASAP. http://dx.doi.org/10.1021/nn303867y

Figure reprinted with permission from Anand S, Paxson AT, Dhiman R, Smith JD, Varanasi KK. 2012. Enhanced condensation on lubricant-impregnated nanotextured surfaces. ACS Nano. Artilce ASAP. http://dx.doi.org/10.1021/nn303867y American Chemical Society.