Recent materials informatics initiatives are fostering the establishment of open-access, federated databases that catalogue the properties of materials. While an initial emphasis, particularly in the case of nanomaterials, is to understand the toxicological properties of materials, a key goal is to establish model-based materials design methodologies wherein materials properties can be computationally predicted. Such a virtual design approach to materials represents a powerful paradigm in which tools become openly available to design new products, optimize materials performance, and understand the risk associated with human and environmental exposure before the materials has been synthesized. Such an infrastructure will benefit industry, academia, and government agencies alike in providing low cost, rapid turn-around approaches to design, and manufacture materials, incorporate into product designs, and establish the regulatory pathway for workforce and consumer protection.

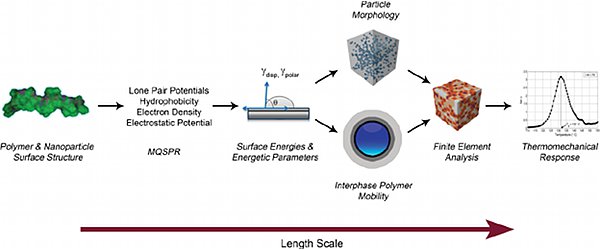

While this scenario presents a futuristic vision, the necessary steps in this direction are being taken with the establishment of the Materials Genome Initiative and the Nanoinformatics initiatives, which include activities in areas such as materials database development, data mining tools, and materials design/design for manufacturing virtual tools. A prime example of implementation of materials design tools was recently reported by Breneman, et. al. in which a data-driven approach to the virtual design of nanostructured polymers was introduced. In this work, the authors implemented materials quantitative structure-property relationship (MQSPR) models to develop a numerical analysis approach to predict the thermomechanical properties of spherical nanofilled polymer composites. The model was validated through a systematic investigation of silica nanoparticles having three different surface chemistries in several polymers.

The work reported is the first time that the MQSPR technique has been utilized across multiple length scales providing the connection between underlying chemistry of the polymer and nanoparticle surface, physics of nanoparticle composite dispersion, and bulk properties of resulting materials. In addition, this approach can further determine the compatibility between the polymer and nanoparticle materials. In combining the MQSPR approach with other materials properties such as contact angle, relative work of adhesion, and work of spreading, additional properties for the composite materials can be predicted such as spherical nanoparticle distributions and change in glass transition temperature from the bulk material. The method can be extended to further design mesoscale and macroscale structures based on the composite properties predicted from the analysis. Thus the potential for extending such models to other materials systems and processes will provide an essential tool connecting emerging materials databases to a digital manufacturing infrastructure that will accelerate future product development and manufacturing.

Figure reprinted with permission: Stalking the Materials Genome: A Data-Driven Approach to the Virtual Design of Nanostructured Polymers. © 2013 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. Authors: Kurt M. Breneman, L. Catherine Brinson, Linda S. Schadler, Bharath Natarajan, Michael Krein, Ke Wu, Lisa Morkowchuk, Yang Li, Hua Deng, Hongyi Xu. DOI: 10.1002/adfm.201301744