Rolith, Inc., a leader in advanced nanostructured devices, is pleased to announce that Printed Electronics Industry selected Rolith for the Best Manufacturing Technology award based on its production of transparent metal mesh conductors for large touch screen displays, OLED lighting and photovoltaics.

Each year the Printed Electronics industry recognizes and awards outstanding achievement to those involved in the rapidly growing printed electronics business. The annual awards were announced at the tenth annual IDTechEx Printed Electronics event this week in Santa Clara, California - the world's largest event on the topic. The awards recognize outstanding progress in the development and commercialization of printed electronics, an industry that produces a huge amount of technical innovation, which will be used in many products, and is now being widely adopted. The entries were judged by both end users and academic judges.

Rolith has won this award for its NanoWeb™ transparent metal mesh conductors technology. NanoWeb has demonstrated superior performance by simultaneously achieving all the most critical features for advanced touch screen display products: (i) high transmission (~ 96%), (ii) low sheet resistance (~ 4 Ohm/sq), (iii) absolute invisibility of metal mesh to the human eye (even in the most stringent illumination conditions) and finally, (iv) complete elimination of parasitic Moiré-fringes, for any display pixel structure. Rolith has also shown that NanoWeb can be fabricated with any metals (Aluminum, Silver, etc.) and rigid glass substrates and flexible PET films.

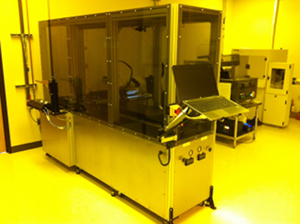

The excellent performance of NanoWeb is achieved due to the sub-micron linewidth of the metal mesh. This fine resolution of patterning is made possible by Rolith’s proprietary manufacturing technology known as Rolling Mask Lithography (RML™), which is based on near-field continuous optical lithography and implemented using cylindrical phase masks. RML also introduces the ability to include the patterning of traces/bezels and the NanoWeb mesh in the same lithographic step, further dropping the cost of touch display manufacturing.

“We are very encouraged by Printed Electronics Industry recognition of our breakthrough technology. NanoWeb’s performance clearly surpasses all ITO alternative technologies currently on the market.”, said Dr Boris Kobrin, founder and CEO, Rolith. He adds: “We are also very excited with the interest in our technology expressed by all major commercial and mobile touch screen display manufacturers. We plan to enter into partnership agreements with some of them in the very near future.”

Source: PRWeb