The recent explosion of wearable consumer products for monitoring physiological information, such as heart rate or skin temperature, provides the promise for personalized medicine wherein an individual’s health status can be continuously evaluated. The evolution of wearable sensor systems will eventually incorporate a host of multivariate sensing technologies capable of analyzing biometric signatures and analytes in sweat enabling the ability to assess disease, physical performance, hydration, and other targeted conditions. Wearable sensor systems will be created by flexible-hybrid electronics manufacturing approaches through which silicon electronics will be integrated with sensors, power and energy harvesting, and wireless communications in wearable form factors. While most commercial product launches have been based on microelectromechanical systems (MEMS) sensors and silicon integrated circuits (ICs), future products will incorporate more components formed by printing. As such, nanomaterials and nanomanufacturing approaches will have a broader impact on wearable sensor and health monitoring applications.

Reference:

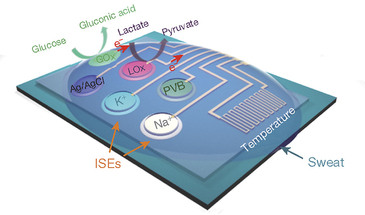

Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Wei Gao, Sam Emaminejad, Hnin Yin Yin Nyein, Samyuktha Challa, Kevin Chen, Austin Peck, Hossain M. Fahad, Hiroki Ota, Hiroshi Shiraki, Daisuke Kiriya, Der-Hsien Lien, George A. Brooks, Ronald W. Davis & Ali Javey. Nature 529, 509–514 (28 January 2016) doi:10.1038/nature16521

Images reprinted with permission from Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Wei Gao, Sam Emaminejad, Hnin Yin Yin Nyein, Samyuktha Challa, Kevin Chen, Austin Peck, Hossain M. Fahad, Hiroki Ota, Hiroshi Shiraki, Daisuke Kiriya, Der-Hsien Lien, George A. Brooks, Ronald W. Davis & Ali Javey. Nature 529, 509–514 (28 January 2016) doi:10.1038/nature16521