Block copolymers

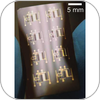

A process for making flexible circuits based on semiconducting carbon nanotube networks and high capacitance ion gel dielectrics through jet printing of liquid inks.

Cobalt nanowires with high perpendicular magnetic anisotropy are formed in a diblock copolymer film template using a pulse-reversed voltage with QCM monitoring. This in situ monitoring system along with the pulse-reversed field enables new control over the magnetic crystal growth.

A perpendicular orientation of cylindrical microdomains in diblock copolymer thin films is achieved by control over polymer-surface interactions. The block which forms cylindrical microdomains is removed by UV exposure and a chemical rinse to yield a nanoporous polymer film. The porous film can be used as a template for electrodeposition of metal nanodots or as a mask for reactive ion etching.

An evaporation-induced flow in solvent cast block copolymer films can produce arrays of nanoscopic cylinders oriented normal to the surface and solvent annealing could markedly enhance the ordering of block copolymer microdomains in thin films. Without removing minor components, solvent-induced surface reconstruction can produce nanoporous structure in thin films. The porous film can be used as a template for deposition of quantum dots or as a mask for pattern transfer to the underneath substrates.

An applied electric field aligns a cylindrical-phase diblock copolymer perpendicular to a substrate. One polymer block is removed by UV exposure and a chemical rinse to yield a nanoporous polymer film. The porous film can be used as a template for electrodeposition of metal nanowires or as a mask for reactive ion etching.